Instructors

The Process Improvement Institute (PII)

instructors have trained more than 7000 technical

and management staff in how to effectively implement PSM,

safety management systems, and reliability programs.

If you do not already know us, come to one of our many

courses offered publicly to check us

out first-hand.

Bill is

President of the Process Improvement Institute (PII).

He has over 30 years of experience, including more than 20

in senior management and senior PSM advisory roles. He is considered one of the leading

authorities on process safety engineering, risk management,

and human error prevention. He has a Bachelor and Masters

degree in Chemical Engineering from the University of Akron

(USA) and he has over 14 years of hands-on chemical industry

experience in process operation, process engineering, process and product

development, management and safety evaluation, and

operations management. He holds 10 US patents, several of which are for

products and processes that are in full, profitable

production today. One factor that makes Mr. Bridges such a

sought after consultant and instructor is his wealth of

hands-on experience in chemical processing and in

implementing PSM in the chemical industry. His last position

in the chemical industry was as a chemical plant manager. Bill is

President of the Process Improvement Institute (PII).

He has over 30 years of experience, including more than 20

in senior management and senior PSM advisory roles. He is considered one of the leading

authorities on process safety engineering, risk management,

and human error prevention. He has a Bachelor and Masters

degree in Chemical Engineering from the University of Akron

(USA) and he has over 14 years of hands-on chemical industry

experience in process operation, process engineering, process and product

development, management and safety evaluation, and

operations management. He holds 10 US patents, several of which are for

products and processes that are in full, profitable

production today. One factor that makes Mr. Bridges such a

sought after consultant and instructor is his wealth of

hands-on experience in chemical processing and in

implementing PSM in the chemical industry. His last position

in the chemical industry was as a chemical plant manager.

Bill has helped many companies in the petroleum,

petrochemical, plastic and chemical process industries

develop, implement and assess PSM and risk management

programs. These programs include consideration of human

factors to prevent human error. Bill has written several

articles on “how to” prevent human error and how to

implement PSM. He serves on the planning committee of AIChE

for international conferences on process safety. Bill has

taught PSM related courses, including process hazard

analysis/HAZOP leadership, incident investigation/RCA, and

management of change (MOC) since 1987. He is an instructor

for several different courses for PII, and also lectures in

American Institute of Chemical Engineers (AIChE) and he

teaches through ASSE-MEC and GPCA in the Middle East. He has trained more

than 5000 in PSM-related and risk analysis-related topics.

Gerald Burch

Gerald

has over 30 years of hands-on manufacturing experience, most

of this in the chemical industry as a plant manager at

Hercules, Engelhard, BASF, and Chemtrade. He has led the

implementation and enhancement of process safety management

systems at all of the sites he has managed. Gerald was an

early adopter and champion of the Responsible Care codes of

management practices, serving on various committees with the

LaPorte (TX) Plant Manager’s Network, the East Harris County

(TX) Manufacturers Council, and the Texas Chemical Council. Gerald

has over 30 years of hands-on manufacturing experience, most

of this in the chemical industry as a plant manager at

Hercules, Engelhard, BASF, and Chemtrade. He has led the

implementation and enhancement of process safety management

systems at all of the sites he has managed. Gerald was an

early adopter and champion of the Responsible Care codes of

management practices, serving on various committees with the

LaPorte (TX) Plant Manager’s Network, the East Harris County

(TX) Manufacturers Council, and the Texas Chemical Council.

Gerald is a skilled team facilitator of continuous

improvement projects (trained in lean manufacturing

techniques, six sigma, human performance improvement, and

process safety) and he has managed large scale,

international change and integration projects following the

sale and acquisition of facilities. He is a skilled PSM

auditor and instructor and has experience implementing all

elements of process safety. Gerald has taught incident

investigation and root cause analysis and process safety and

safety leadership course.

He has a BS in Chemical Engineering from the University of

Virginia and a MBA in Leadership from William Carey

University. He has served on the Board of Directors of the

George Washington University Center for the Study of

Learning and he led Virginia’s High Performance Learning

Network.

Dr. Tony Clark

Tony

has a PhD in Chemical Engineering and began his career teaching chemical engineering to HND and B.Eng (Hons.) students at the Polytechnic of Wales,

he then moved into consultancy and has more than 30 years

experience in the fields of safety, loss prevention and

environmental assessments. His work has included preparation

of safety reports and QRA studies for a variety of onshore

and offshore oil and gas installations, chemical and

petrochemical plants both in the UK and overseas, and in

particular the Middle East. In the early 1990’s he was

seconded to BP Exploration in Scotland where he was a safety

coordinator for a large offshore gas development. Tony’s

training experience includes devising and presenting a

training program covering the techniques of HAZOP, Hazard

Analysis, and elements of PSM to the Chinese in Xinjiang. He

has delivered hazard assessment and emergency planning

training to Indian engineers, risk assessment and

environmental analysis training in the Middle East.

Tony continues to

deliver consulting and training services to clients in UK,

Europe, and the Middle East, including LOPA analysis, PHAs,

HAZOPs, quantitative risk assessments, SIS determination and

verification, etc. Tony

has a PhD in Chemical Engineering and began his career teaching chemical engineering to HND and B.Eng (Hons.) students at the Polytechnic of Wales,

he then moved into consultancy and has more than 30 years

experience in the fields of safety, loss prevention and

environmental assessments. His work has included preparation

of safety reports and QRA studies for a variety of onshore

and offshore oil and gas installations, chemical and

petrochemical plants both in the UK and overseas, and in

particular the Middle East. In the early 1990’s he was

seconded to BP Exploration in Scotland where he was a safety

coordinator for a large offshore gas development. Tony’s

training experience includes devising and presenting a

training program covering the techniques of HAZOP, Hazard

Analysis, and elements of PSM to the Chinese in Xinjiang. He

has delivered hazard assessment and emergency planning

training to Indian engineers, risk assessment and

environmental analysis training in the Middle East.

Tony continues to

deliver consulting and training services to clients in UK,

Europe, and the Middle East, including LOPA analysis, PHAs,

HAZOPs, quantitative risk assessments, SIS determination and

verification, etc.

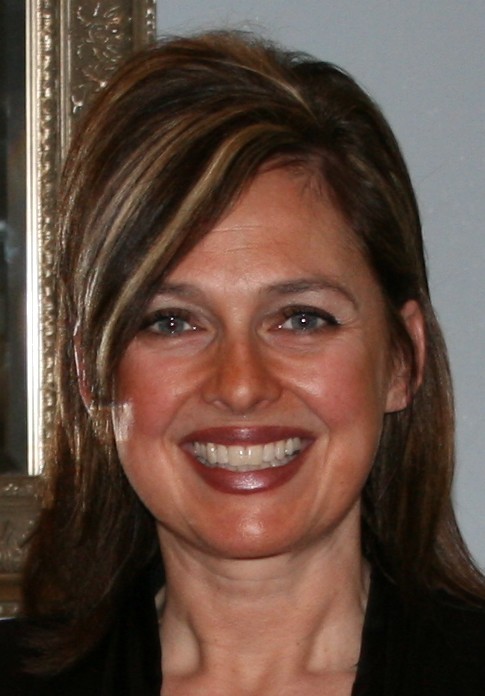

Ginette

has more 15 years experience overall and 12 years of experience in the Pharmaceutical/

Biopharmaceutical Industries. She has worked for companies

like Wyeth, Schering Plough, Johnson & Johnson, and Bristol

Myers Squibb leading the technical training, regulatory

training, and organizational development efforts. Ginette has a Ph.D. in Industrial-Organizational Psychology

from the Interamerican University of Puerto Rico. The

first half of her career was focused on the development and

implementation of training programs and employee performance

improvement initiatives. The last years she has been

focusing on Human Reliability and Productivity Improvement

initiatives and has achieved up to 60% reduction on human

error events related to product quality, and up to 50%

reduction on departments allocated budget by increasing

efficiencies and simplifying processes. Ginette

has more 15 years experience overall and 12 years of experience in the Pharmaceutical/

Biopharmaceutical Industries. She has worked for companies

like Wyeth, Schering Plough, Johnson & Johnson, and Bristol

Myers Squibb leading the technical training, regulatory

training, and organizational development efforts. Ginette has a Ph.D. in Industrial-Organizational Psychology

from the Interamerican University of Puerto Rico. The

first half of her career was focused on the development and

implementation of training programs and employee performance

improvement initiatives. The last years she has been

focusing on Human Reliability and Productivity Improvement

initiatives and has achieved up to 60% reduction on human

error events related to product quality, and up to 50%

reduction on departments allocated budget by increasing

efficiencies and simplifying processes.

She has authored various

publications on Human Reliability and Employee Productivity

topics including "Model for Collective Behavior Modification

in Organizations" and "Coding, Monitoring, and Trend

Analysis on Human Error Investigations" and "Creating an

Effective CAPA Effectiveness Program." Having

implemented Human Reliability programs in various

industries, she understands what works and what doesn’t when

trying to change a culture from an error tolerant

environment to an error free organizational community.

She has designed and delivered hundreds of courses through

her career including, Incident Investigation/Root Cause

Analysis (RCA) Leadership, Instructors Qualification

Program, Skill-Based Training Program for SME’s, Human Error

Prevention for Operators, and Supervisors Academy for an

Error Free Environment.

Ron is Managing Partner of The RM Group, Inc., Knoxville,

TN. He travels worldwide working with manufacturing

companies in North America, Europe, Australia, Africa, and

the Far East.

Ron is author of the book Making Common Sense

Common Practice: Models for Manufacturing Excellence,

which describes one company’s journey to world class

performance. His latest book is What Tool? When?

Selecting the Right Manufacturing Improvement Tools,

is scheduled for release in December, 2006. He has also

written over 30 journal articles worldwide. Ron served for

five years as President of Computational Systems, Inc (CSI),

the leading supplier of industrial instruments and software

for equipment condition monitoring technologies. During his

five-year tenure, the company grew at 30% per year, while

concurrently maintaining healthy profits and cash position,

and a strong balance sheet. He holds a BSME, MSME, MBA, PE,

and CMRP.

Mickey

has more than 40 years of process engineering experience,

with over 25 years in operations and

operations management. He was plant manager of three

different facilities involved in the large scale production

of highly toxic and flammable chemicals. He has led many

process hazard analyses (PHAs), including a great many

management of change reviews. He has led many

investigations and root cause analysis (RCAs) and several

large scale process safety audits and assessments. He was a

principal trainer for PHA leadership and process safety

management (PSM) courses within Arch Chemical Company for

several years and had overall responsibility for PSM

implementation at both the plant and corporate levels of

Olin Chemicals and Arch Chemicals. He has B.S. Chemical

Engineering. He has served on book writing committees for CCPS/AIChE and he is an active member of NFPA, serving on

several standards committees. Mickey

has more than 40 years of process engineering experience,

with over 25 years in operations and

operations management. He was plant manager of three

different facilities involved in the large scale production

of highly toxic and flammable chemicals. He has led many

process hazard analyses (PHAs), including a great many

management of change reviews. He has led many

investigations and root cause analysis (RCAs) and several

large scale process safety audits and assessments. He was a

principal trainer for PHA leadership and process safety

management (PSM) courses within Arch Chemical Company for

several years and had overall responsibility for PSM

implementation at both the plant and corporate levels of

Olin Chemicals and Arch Chemicals. He has B.S. Chemical

Engineering. He has served on book writing committees for CCPS/AIChE and he is an active member of NFPA, serving on

several standards committees.

Greg has more

than 17 years of process engineering experience, with 25+

years experience overall. He has extensive hands-on

experience in chemical operations, which includes

responsibility for effectively implementing process safety

at sites for Cytec, Degussa, and Hoechst Celanese. His last

position in the chemical industry was as operations manager.

He also has experience in performing process hazard analyses

(PHAs), investigations, and audits, and he has experience

implementing behavior-based safety programs and incident

reporting systems. He has extensive experience in helping

clients implement process safety. He has similar

experience with roll-out and implementation of Site Security

and Site Vulnerability Assessments; for instance he

led the Synthetic Organic Chemical Manufacturer’s

Association (SOCMA) efforts in security, management systems

development, training, and member outreach.

He is

currently leading PHAs and PHA Revalidations and he is also

teaching PHA Leadership courses and other topics for PII.

He has B.S. Chemical Engineering. Greg has more

than 17 years of process engineering experience, with 25+

years experience overall. He has extensive hands-on

experience in chemical operations, which includes

responsibility for effectively implementing process safety

at sites for Cytec, Degussa, and Hoechst Celanese. His last

position in the chemical industry was as operations manager.

He also has experience in performing process hazard analyses

(PHAs), investigations, and audits, and he has experience

implementing behavior-based safety programs and incident

reporting systems. He has extensive experience in helping

clients implement process safety. He has similar

experience with roll-out and implementation of Site Security

and Site Vulnerability Assessments; for instance he

led the Synthetic Organic Chemical Manufacturer’s

Association (SOCMA) efforts in security, management systems

development, training, and member outreach.

He is

currently leading PHAs and PHA Revalidations and he is also

teaching PHA Leadership courses and other topics for PII.

He has B.S. Chemical Engineering.

Revonda

has 20+ years experience in the chemical industry, including

process development, process engineering, and process safety

management and evaluation. She holds one US patent. Revonda

has a B.S. in Chemical Engineering from North Carolina State

University and a MBA from the University of North Carolina’s

Kenan-Flagler Business School. The first 8 years of her

career was hands-on in the chemical industry. In the early

1990’s Revonda led the PSM compliance initiative at a large

chemical manufacturing facility, authoring policies and

procedures to address industry, regulatory, and company

standards, as well as managing their implementation. Revonda

has been involved with plant emergency response teams as a

responder and an incident command post team member. Revonda

has 20+ years experience in the chemical industry, including

process development, process engineering, and process safety

management and evaluation. She holds one US patent. Revonda

has a B.S. in Chemical Engineering from North Carolina State

University and a MBA from the University of North Carolina’s

Kenan-Flagler Business School. The first 8 years of her

career was hands-on in the chemical industry. In the early

1990’s Revonda led the PSM compliance initiative at a large

chemical manufacturing facility, authoring policies and

procedures to address industry, regulatory, and company

standards, as well as managing their implementation. Revonda

has been involved with plant emergency response teams as a

responder and an incident command post team member.

Revonda

has PSM training from AICHE/CCPS including Process Safety

Documentation and Engineering Design for Process Safety.

Other training includes PHA Leader and Incident

Investigation Leader training. She has significant hands-on

experience having participated in, led and documented over

40 PHAs, numerous management of change (MOC) risk reviews,

performed many MOC approvals, participated or led several

investigations, and participated or led many PSM compliance

audits and PSM assessments. She has also developed customized training materials

for various topics, including MOC, PHA leadership, and PSM

auditing, and she is a co-instructor for these topics and

for incident investigation. Revonda has experience with both

community relations and crisis management and is currently

involved in LEPC activities, her local Community Emergency

Response Team (CERT), and is a “Together We Prepare”

disaster preparedness volunteer and trainer with the

American Red Cross. For the past 6 years of her career, she

as been a consultant to the chemical industry, were she has

provided PSM-related and PHA/HAZOP training and consulting.

Mr.

Woody has over 20 years of engineering and safety management

experience supporting various nuclear and chemical

operations including nuclear weapons production, facility

decommissioning, environmental restoration projects, and

chemical plant operations and safety management. He has a

Bachelor of Science degree in Civil Engineering from the

University of Tennessee. During Mr. Woody’s career, he served as

a Senior Safety Engineer with US Department of Energy’s

(DOE) Office of Defense Programs (DP), where he performed

hazard and accident analysis at major nuclear installations.

For the past ten years, Mr. Woody has been a safety

consultant providing regulatory support, safety analysis,

and training. He has been part of the development team for

many of the definitive standards with DOE on hazard

identification, hazard and risk characterization, and

integrated process safety management and environmental

systems. He is experienced and capable with various types of

chemical and radiological dispersion analysis including

ALOHA and HOTSPOT. Mr.

Woody has over 20 years of engineering and safety management

experience supporting various nuclear and chemical

operations including nuclear weapons production, facility

decommissioning, environmental restoration projects, and

chemical plant operations and safety management. He has a

Bachelor of Science degree in Civil Engineering from the

University of Tennessee. During Mr. Woody’s career, he served as

a Senior Safety Engineer with US Department of Energy’s

(DOE) Office of Defense Programs (DP), where he performed

hazard and accident analysis at major nuclear installations.

For the past ten years, Mr. Woody has been a safety

consultant providing regulatory support, safety analysis,

and training. He has been part of the development team for

many of the definitive standards with DOE on hazard

identification, hazard and risk characterization, and

integrated process safety management and environmental

systems. He is experienced and capable with various types of

chemical and radiological dispersion analysis including

ALOHA and HOTSPOT.

Mr. Woody is trained in process hazards analysis (PHA)

and incident investigation, and has completed advanced

studies in Maintenance Management. And he completed the

Reactor Safety course at the Massachusetts Institute of

Technology. He has developed and delivered numerous training

classes to hundreds of individuals on various safety-related

topics, including Integrated Safety Management, Technical

Safety Requirements, and Safety Analysis Review Process. He

is a co-instructor of PII’s courses on PHA and investigation

leadership, and he provides consulting services in many

areas of PSM implementation, safety management system

evaluation and implementation, consequence modeling, hazard

evaluation, PHA leadership, risk assessment, and accident

investigation. |