PII Courses

Course 1

Overview of Process

Safety Management (PSM)

Course

2

Process Safety Management

(PSM)

Course

3

Compliance Auditing for

Process Safety

Course

4

Incident

Investigation/Root Cause Analysis Leadership

Course 4-0

Incident Investigator/Root Cause Analyst

Training

Course

5

Writing Effective

Operating and Maintenance Procedures

Course

6

Mechanical Integrity

Course

7

Management of Change and

PSSR

Course

8

PHA/HAZOP Leadership

Course 8-0

PHA Overview Training

Course

9

PHA Revalidation

Course 10

Human Error Prevention

Course 11

Layer of Protection

Analysis

Course 12

Safety

Integrity Systems

Course 13

Job Safety Analysis

Course 14

Human Error Prevention - for Workers

Course 15

Safety Task Action Reporting (STAR)

Course

16

Behavior-Based Safety

Course

17

Selecting the Right Manufacturing Improvement

Tools

Course

18

Reliability Leadership for Manufacturing

Excellence

|

Course 7: Management of Change & Pre-Startup Safety

Review (2-Day)

Courses |

Calendar |

Instructors |

Course Registration |

Private Training |

Coaching

Recommended prerequisites:

Participants should have practical, technical experience in

design, operation, or maintenance of complex systems.

MOC is the element for which all other “foundation”

elements of PSM are implemented. It is the PSM element that

controls introduction of new risk. Recognizing change,

analyzing the risk of each change, and handling small

changes efficiently are just some of the barriers that

managers face with MOC implementation. This 2-day course

explores proven strategies for implementing a workable MOC

system and customized approaches to fit your company’s

culture. It also shows how to implement physical and

instrumentation changes through the proper use of pre-startup

safety review (PSSR) systems, sometimes called operational

readiness reviews (ORRs). Written examples of programs for

addressing simple and complex changes are included in the

course notebook. MOC is the element for which all other “foundation”

elements of PSM are implemented. It is the PSM element that

controls introduction of new risk. Recognizing change,

analyzing the risk of each change, and handling small

changes efficiently are just some of the barriers that

managers face with MOC implementation. This 2-day course

explores proven strategies for implementing a workable MOC

system and customized approaches to fit your company’s

culture. It also shows how to implement physical and

instrumentation changes through the proper use of pre-startup

safety review (PSSR) systems, sometimes called operational

readiness reviews (ORRs). Written examples of programs for

addressing simple and complex changes are included in the

course notebook.

Typical Course Candidates Typical Course Candidates

- Technical Managers and Supervisors

- HSE professionals

- Quality control managers and staff

- Engineers

- PSM coordinators

- Most other operation, maintenance, reliability, and

quality staff who are involved with designing, implementing,

tracking, and evaluating MOC programs

What You Will Learn

- Requirements of a complete MOC System

- What PSSR is and how it works and how it can be combined

with MOC and mechanical integrity systems

- How to realistically control both small and large changes,

minimizing employees’ needs to bypass the system

- Simple frameworks for identifying and analyzing risks

associated with a recommended change to help ensure the

minimum losses to your company (this is the heart of any MOC

system)

- Training needs and requirements for all levels of your

organization necessary to make managing change a functional

system.

- How to integrate all company systems for managing specific

functional changes into one MOC system to handle PSM, HSE,

quality control, reliability, and productivity changes; and

learn why this integration is so important

Take Home:

- Training tools for teaching your employees to

recognize the difference between a replacement-in-kind

and a change (take home copies included)

- Copies of real MOC and PSSR written programs, forms, and

checklists of risk review & PSSR questions

- Electronic (PDF) copy of course notebook

- A Certificate of Completion

- 1.3 CEUs or 1.3 COCs

Course Outline

Day 1 (8:00 a.m. to 5:00 p.m.)

- Introduction

- Learning objectives and overview of PSM

- Overview of PSM

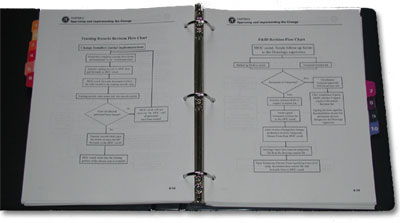

- Overview of MOC and PSSR

- Workshop: Identifying which MOC failures led to a

catastrophe

- Recognizing or proposing changes

- Review of basic definitions of replacement-in-kind (RIK)

and not-

replacement-in-kind (NRIK)

- Workshop: RIK vs NRIK Quiz

- Workshop: Developing RIK and NRIK examples for your

company

- Initiating the change request

- Who does what?

- Initiating the change request form

- Example of change request forms

- Reviewing the proposed change

- Technical reviews and Risk reviews

- Workshop: Choosing the appropriate risk review method for

a

minor mechanical change

- Workshop: Performing a risk review of a minor mechanical

change

Day 2 (8:00 a.m. to 3:30 p.m.)

- Reviewing the proposed change (continued)

- Workshop: Performing a risk review of a minor procedure

change

- Approving and implementing the change

- Roles, responsibilities, and authorities

- Tracking the change request through closure

- Pre-Startup Safety Reviews

- Definitions and Style of PSSRs

- Combining PSSR with other PSM or Reliability systems

- Workshop: PSSR Quiz

- Workshop: Performing a PSSR for a minor mechanical change

- Overall Roles and Responsibilities

- Managing the MOC/PSSR program(s)

- MOC/PSSR scope decisions

- Review of typical MOC Program in notebook

- Review of typical PSSR Program in notebook

- Key Performance Indicators

- Workshop: Implementation planning

- Optional Exam

More Information

Instructor(s):

Bill Bridges is a primary instructor for this course. He

has taught this course many times over the past 3 years. To

find our more about this course or to check into having this

course taught at your site; contact Mr. Bridges at

1.865.675.3458 or by e-mail at

wbridges@p-i-i-i.com.

Revonda Tew is a primary instructor for this course.

She has many years of PSM implementation experience, MOC

implementation experience, and training experience.

Feel free to contact Mrs. Tew at

rtew@p-i-i-i.com.

Schedule:

>>

See the Calendar of Publicly Offered Training.

This course can also be taught (either as-is or

customized) at your site. Please contact PII for details

about having our training provided at your site.

Pricing for Public Offerings (per student):

$795.00 USD

Registration Information: >>

Click here to register for this

course.

|